-

Product DescriptionCompany Info.<>

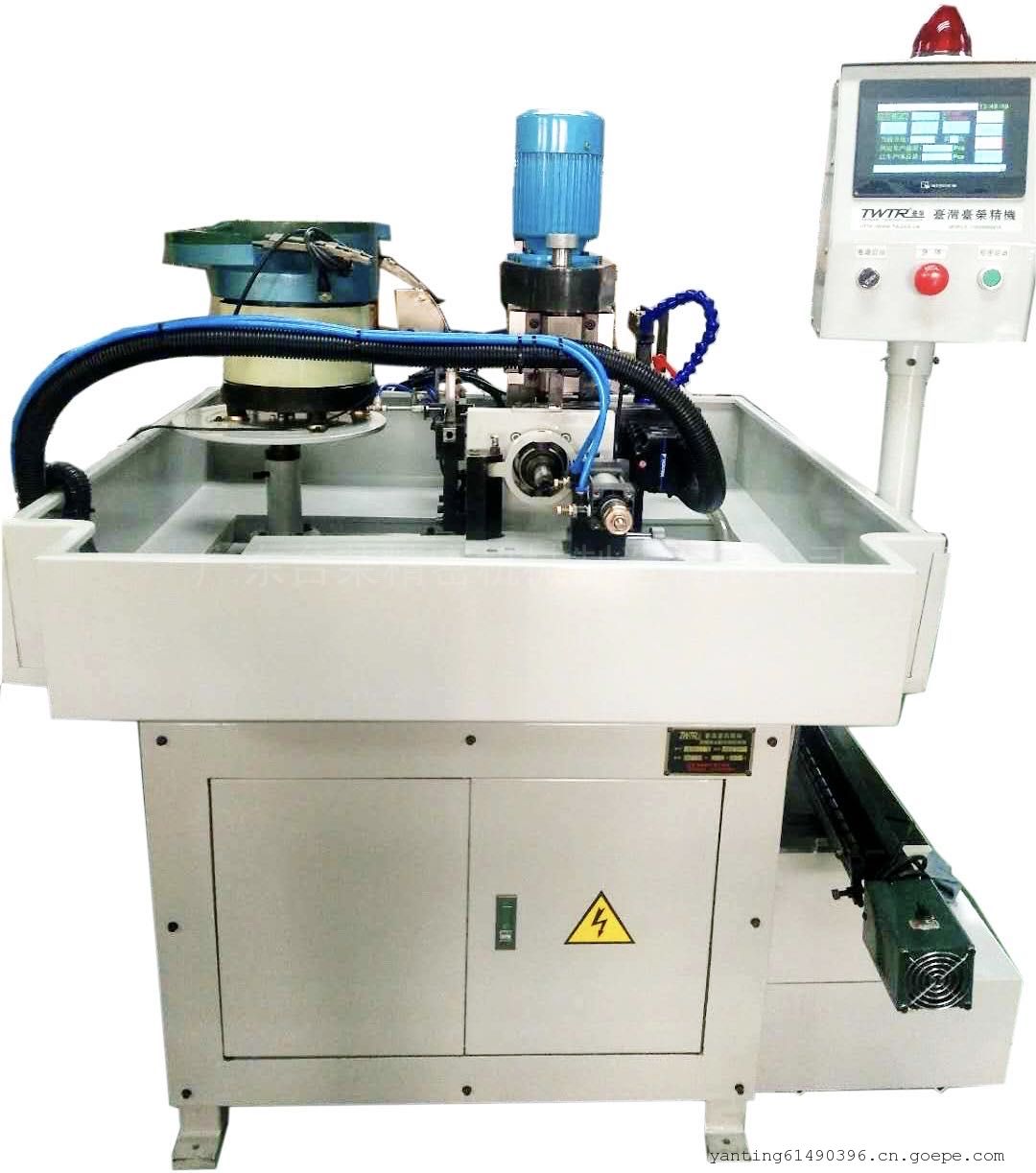

- Types:

- Multi-function milling machine

- Control form:

- PLC

- Layout form:

- Vertical type

- Inventory or not:

- Yes

- Model:

- Three-axis flattening machine

- Weight:

- 600 Kg

- Main motor power:

- 0.75 kw

- Spindle speed range:

- 2860 rpm

- Workbench size:

- 1200*750*1600 mm

- Taper of spindle taper hole:

- /

- Number of T-slots:

- 3

- Action object:

- Hardware

- Action object material:

- Metal

- Applicable scope:

- Special

- Applicable industry:

- General purpose

TAIRONG THREE AXIS FLAT MILLING MACHINE PROCESSING HEXAGON SQUARE MACHINE AUTOMATIC INDEX MILLING MACHINE

Our company's flat milling machine processes the above products, which can save labor costs and increase product quantity. Help users compete in quality and cost.

After the change of processed products, the adjustment of the machine is relatively convenient, only need to make the corresponding parts processing fixture or jaw (clamp specific do not need to replace) and feeding part, equipped with the corresponding blade, while adjusting the speed of the cutter shaft, blade position can be adjusted very conveniently, the adjustment of the left and right direction of the cutter housing seat is equipped with a handle with scale, adjustment for reference. The machine is quite stable. In the production process, only the size change caused by tool wear needs to be adjusted after a period of time. The operator only needs to simply put the workpiece into the blanking groove according to the required direction. The processing process is automatically completed by PLC control. The operator can also sample the quality of the product. Usually, each person can operate three machine tools, saving manpower. This machine is suitable for mass processing products with high precision requirements. Our unique fixture design can meet the processing requirements of various shapes of parts and meet the different requirements of customers. According to the customer's parts to be processed and processing requirements, design and manufacture the required fixtures and other corresponding parts for customers.- Name(chinese)

- Name(English)

- Guangdong Tairong Precision Machinery Manufacturing Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Dongguan, Guangdong, China

- Nearby port

- Shenzhen

The company always adheres to the policy of putting quality and reputation first, and has established a one-stop quality management system from the processing of parts to the factory of the whole machine. We not only provide various automatic lathes: Taiming automatic lathe, Xinmingyang automatic lathe, cam CNC automatic lathe, etc., but also various feeders: full-function oil film automatic feeder, automatic bar feeder, hydraulic feeder, etc. After automatic lathe processing, secondary processing of supporting equipment: Tooth rolling machines, small horizontal milling machines, flat milling machines, knife sharpening machines, etc., as well as various spare parts. The design and development of products are consistent, economical and environmentally friendly. At the same time, we actively cooperate with many machinery companies, constantly absorb and learn from foreign advanced technology, constantly innovate and constantly improve. Advantages of automatic feeders and receivers for automatic lathes and table lathes: The key parts of the equipment are selected from products named in Japan and Taiwan. While ensuring the high quality of the whole machine, our equipment is highly price competitive and helps you reduce costs.- Name(chinese)

- Name(English)

- Guangdong Tairong Precision Machinery Manufacturing Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Dongguan, Guangdong, China

- Nearby port

- Shenzhen

The company always adheres to the policy of putting quality and reputation first, and has established a one-stop quality management system from the processing of parts to the factory of the whole machine. We not only provide various automatic lathes: Taiming automatic lathe, Xinmingyang automatic lathe, cam CNC automatic lathe, etc., but also various feeders: full-function oil film automatic feeder, automatic bar feeder, hydraulic feeder, etc. After automatic lathe processing, secondary processing of supporting equipment: Tooth rolling machines, small horizontal milling machines, flat milling machines, knife sharpening machines, etc., as well as various spare parts. The design and development of products are consistent, economical and environmentally friendly. At the same time, we actively cooperate with many machinery companies, constantly absorb and learn from foreign advanced technology, constantly innovate and constantly improve. Advantages of automatic feeders and receivers for automatic lathes and table lathes: The key parts of the equipment are selected from products named in Japan and Taiwan. While ensuring the high quality of the whole machine, our equipment is highly price competitive and helps you reduce costs. -

Send your message to this supplier*From:*To:

Ms. Tina

*Message:

Ms. Tina

*Message:

Copyright © 2003 - 2025 Goepe.com All rights reserved.